In the world of small business, two pillars stand as the foundation of success: providing a fulfilling customer experience and mastering inventory management. These two aspects are deeply interconnected. The magic behind a seamless customer experience often lies in strategic inventory management — ordering, storing, and tracking products in a way that ensures availability without the fear of stockouts.

Effective inventory management ensures that your customers can place their orders confidently, knowing that their products will be available and delivered promptly.

However, the challenge for small business owners lies in balancing the act. Overstocking ties up your working capital and increases storage costs, while understocking risks losing customers and sales opportunities. This delicate balance requires a strategic approach to inventory management — one that maximizes efficiency and minimizes costs.

In this guide, we’ll explore how you can streamline your inventory management process with the help of modern inventory management software. We’ll delve into practical tips and best practices that will help you effectively manage your stock levels and drive your small business toward success.

Let’s dive in.

Table of Contents

The Importance of Inventory Management Software

Previously, efficient inventory control was often limited to large enterprises using expensive Enterprise Resource Planning (ERP) systems. Small businesses, on the other hand, were typically constrained to using spreadsheets for their inventory needs.

While spreadsheets can handle basic inventory tracking, they fall short in managing complex inventory tasks, real-time data synchronization, and scalability, often leading to errors and inefficiencies.

However, the landscape has changed dramatically. Technology has become more accessible and affordable, leveling the playing field for small businesses. Today, modern inventory management software like QuickBooks and Linnworks offers robust, integrated solutions that seamlessly fit into various business operations.

These tools bring powerful capabilities to small businesses, enabling them to manage their inventory with the same precision and efficiency as larger enterprises.

Let’s delve deeper into how an inventory management system can benefit your small business.

Real-time stock management

Modern inventory management systems provide up-to-the-minute tracking of stock levels, movements, and locations. Unlike static spreadsheets, which require manual updates and can quickly become outdated, these systems offer real-time insights. This real-time visibility helps prevent stockouts, reduces overstocking, and ensures that inventory decisions are based on the most current data.

Centralized product database

Managing inventory across stores at multiple locations can be challenging. However, with inventory management software, you can centralize your product database, integrating all product information — including SKUs, descriptions, and stock levels — into one cohesive system. This centralization ensures consistency and accuracy across all sales channels and locations, reducing the risk of discrepancies and streamlining your operations.

Improved efficiency and saves time

A manual inventory system can be labor-intensive, time-consuming, and also susceptible to human error. An inventory management system minimizes these risks by automating repetitive tasks and providing accurate, real-time data. This efficiency reduces the workload on your staff, allowing them to focus on more strategic aspects of the business.

Automated order management

Keeping track of when to reorder stock manually is time-consuming and can lead to mistakes. A good inventory management system enables you to automate the process of placing the order when inventory reaches a certain threshold. This automation not only saves time but also ensures that orders are placed promptly, keeping inventory levels optimized and reducing the risk of running out of stock.

Enhanced customer satisfaction

Timely and accurate inventory management ensures that your customers have access to the products they want when they want them. By reducing the chances of stockouts and backorders, inventory management software enhances the customer experience, leading to increased satisfaction and loyalty.

Scalability

When your business starts to grow, so will your inventory levels. Inventory management systems can easily accommodate and manage an increasing number of products, sales channels, and transactions without a decline in efficiency. Thus, your inventory processes remain robust even as your operations expand.

Key Inventory Management Techniques

Various types of inventory management techniques can be applied depending on the type of business and the products being analyzed. Here’s a look at three key inventory management techniques suitable for small businesses: ABC Analysis, Demand Forecasting, and Lean Management.

ABC Analysis

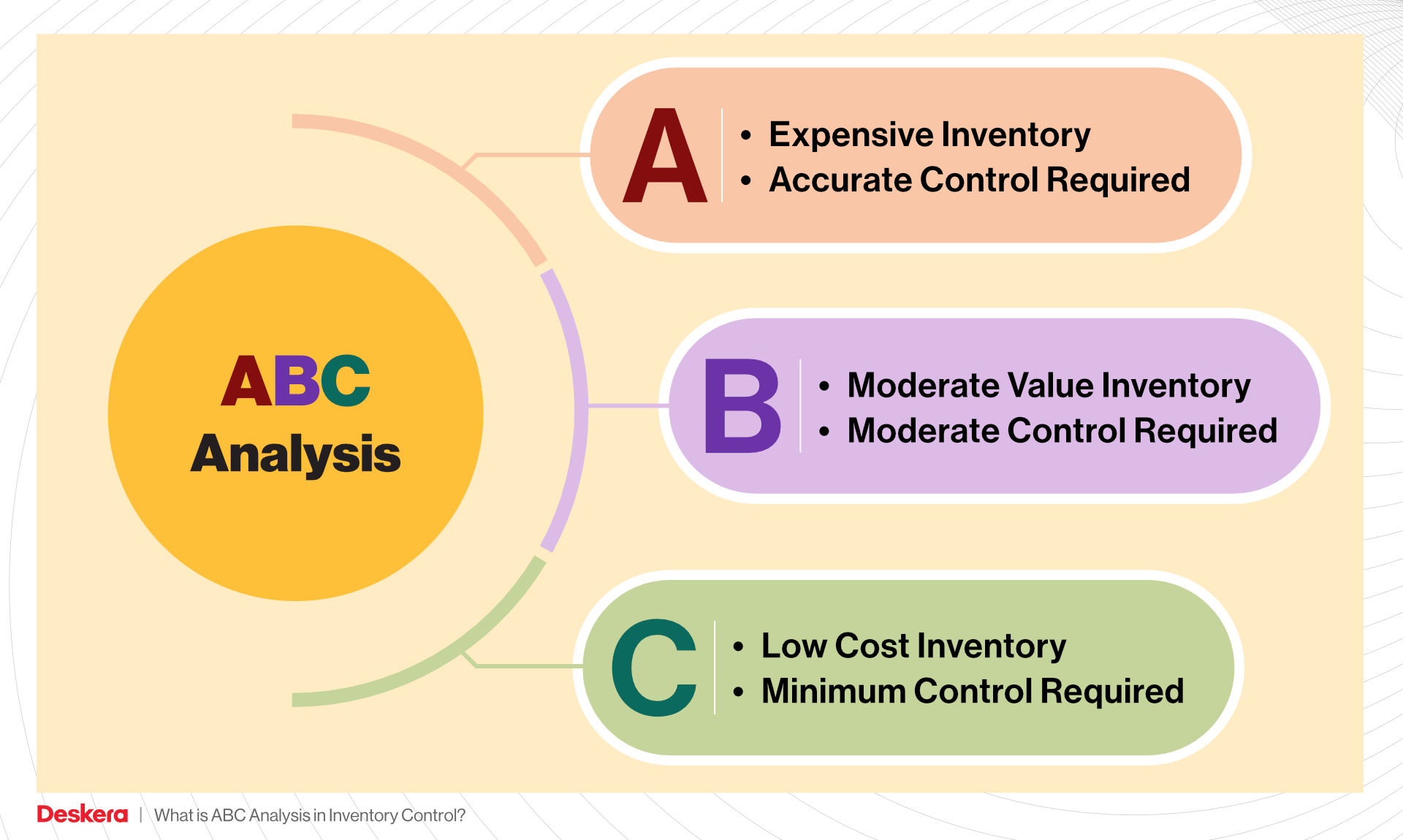

ABC Analysis is an inventory management technique that categorizes inventory into three distinct groups — A, B, and C — based on their value and sales volume.

- A: Items are high-value products with low sales frequency, requiring close monitoring and tight control.

- B: Items represent moderate-value products with a moderate sales frequency, needing a balanced approach to management.

- C: Items are low-value products with high sales frequency and can be managed with a more relaxed control since their impact is minimal.

As small businesses often have limited resources, ABC analysis allows them to prioritize their products and efforts. By effectively categorizing and managing inventory, businesses can optimize stock levels, reduce holding costs, and improve order fulfillment efficiency.

Demand Forecasting

Demand forecasting involves predicting future inventory needs based on historical sales data, market trends, and external factors such as seasonality and economic conditions. An advanced inventory management solution analyzes past sales patterns and current market dynamics to estimate the future demand for their products.

By organizing your warehouse layout efficiently, you can significantly boost productivity and streamline inventory management. One effective solution to optimize storage space is using pallet rack shelving. This type of shelving helps in categorizing products better and enhancing accessibility, ultimately improving order fulfillment times.

This predictive insight allows businesses to plan their inventory purchases and stock levels more accurately. It helps them avoid the pitfalls of overstocking and understocking. Also, it leads to more informed purchasing decisions, better cash flow management, and enhanced customer satisfaction by ensuring that the right products are available at the right time.

Lean Management

Lean management techniques were first introduced in Japan during the 1960s and 1970s. The principle behind this approach is to minimize waste while maximizing efficiency. Essentially, this approach guides you to identify and eliminate excess inventory and unnecessary handling to streamline operations and reduce costs.

Key strategies in lean inventory management include Just-In-Time (JIT) inventory, which reduces holding costs by receiving goods only as they are needed, and Continuous Improvement (Kaizen), which encourages regular assessment and enhancement of inventory practices.

By applying lean principles, businesses can achieve a more agile and responsive inventory system, reduce waste and cost, and increase overall operational efficiency.

Advanced Strategies for Inventory Optimization

You have learned about various inventory management techniques. However, if you aim to master inventory optimization, you need to leverage advanced strategies that include analyzing key performance indicators (KPIs), making seasonal adjustments, and integrating multiple sales channels.

Let’s first talk about the role of KPIs in inventory optimization.

KPIs in inventory management

KPIs are essential tools in measuring and improving inventory management efficiency. By focusing on specific KPIs, businesses can gain valuable insights into their inventory processes and make data-driven decisions.

Here are three important KPIs to track:

Inventory turnover: This metric determines how often inventory is sold and replaced over a certain period. To calculate inventory turnover, use the formula:

Inventory turnover = Cost of Goods Sold (COGS) / Average Inventory

A high inventory turnover rate indicates that products are selling quickly, reducing the risk of obsolescence and minimizing holding costs. Whereas a low turnover rate suggests excess inventory and potential inefficiencies.

Monitoring this KPI helps businesses optimize their stock levels, ensuring that inventory is aligned with sales velocity.

Gross Margin Return on Investment (GMROI): GMROI assesses the profitability of inventory by comparing the gross profit earned to the cost of the inventory. It measures how much gross profit is generated for each dollar invested in inventory. The formula for GMROI is:

GMROI = Gross Profit / Average Inventory Cost

A higher GMROI indicates that the inventory is generating profits.

Order Accuracy: This KPI measures the percentage of customer orders delivered correctly without errors such as incorrect items or quantities. High order accuracy indicates good customer satisfaction and reduces the costs associated with returns and re-shipping. To calculate order accuracy:

Order Accuracy = (Number of Correct Orders / Total Number of Orders)×100

Improving order accuracy minimizes disruptions in supply chain management and enhances the overall customer experience.

Seasonal adjustments and multi-channel integration

A successful inventory management process accounts for seasonal customer demands and the complexity of managing multiple sales channels. A good inventory management tool understands these dynamics and calculates the minimum order quantity to prevent overstocking and stockouts.

Seasonal adjustments

Seasonal variations significantly impact inventory levels. Retailers may see increased demand for certain products during holidays or specific times of the year. For instance, customer demand for woolen jackets will rise during the winter season, just as demand for air conditioners increases during the summer.

Implementing seasonal adjustments involves analyzing historical sales data to predict demand spikes and troughs. Using this data, businesses can adjust their inventory levels in anticipation of seasonal changes. This ensures they have sufficient stock during peak periods and avoid excess inventory during off-peak times.

Accounting for seasonal adjustments enables retail stores to strategize their inventory levels effectively:

- Increase inventory ahead of high-demand seasons to meet anticipated sales.

- Offer clearance sales on remaining stock after peak seasons.

- Align promotions with seasonal trends to boost sales and manage inventory efficiently.

Multi-channel integration

For successful inventory management, businesses need clear visibility across all channels, including online stores, physical locations, and third-party marketplaces. A cohesive approach is required to ensure consistency and accuracy.

Multi-channel integration involves using inventory management solutions to synchronize stock levels and sales data across all channels. This integration helps prevent issues like overselling or stockouts, which can occur when inventory is not updated in real time across channels.

Key strategies for multi-channel integration include the following.

- Centralized inventory system: Implement a unified inventory management system that provides a real-time overview of stock across all channels. Tools like EazyStock and Linnworks can synchronize inventory data, ensuring that stock levels are accurate and up-to-date.

- Cross-channel fulfillment: Leverage inventory from different locations to fulfill orders. For example, an online order can be fulfilled from a nearby physical store if the central warehouse is out of stock. Using a multi-store inventory management app can help businesses sync stock levels across multiple locations, ensuring efficient order fulfillment and minimizing stock discrepancies.

- Consistent pricing and promotions: Ensure that pricing and promotional strategies are consistent across all channels to avoid customer confusion and maintain brand integrity.

You might also be interested in 8 Game-Changing eCommerce Integrations For 4X Growth

Lesser Known Tips for Enhanced Inventory Control

In addition to well-established inventory management techniques, several other strategies can aid effective inventory management.

Outsourcing inventory management tasks

While having robust inventory software can solve many problems, there are situations where outsourcing certain inventory management tasks is beneficial.

For instance, in industries like pharmaceuticals, where stringent regulations govern storage, handling, and distribution, outsourcing to specialized providers can ensure compliance with industry standards and regulatory requirements.

A third-party logistics provider (3PL) with expertise in pharmaceuticals can manage temperature-sensitive inventory, handle intricate distribution channels, and comply with Good Distribution Practices (GDP). This specialization reduces the risk of costly errors and regulatory penalties while enhancing the reliability of inventory processes.

Additionally, if your business processes are complex and require significant investment in infrastructure or personnel, outsourcing can be a viable solution. It provides access to advanced technologies and specialized skills that may be too costly or complex to develop in-house.

Finally, outsourcing non-core inventory management tasks allows businesses to allocate more resources and attention to areas that directly contribute to growth and innovation. This can lead to improved product development, better customer service, and enhanced competitive positioning.

Strategic partnerships and volume discounts

Building strong relationships with suppliers and negotiating volume discounts are powerful strategies for enhancing control and reducing inventory costs. Here’s how you can take advantage of them.

Strategic supplier relationships

Focus on developing long-term relationships with your suppliers. This can help with flexible payment schedules, access to new product lines, and, most importantly, priority during shortages.

Strategic partnerships also involve collaboration on inventory planning and forecasting, helping suppliers align with your inventory needs and thereby reduce lead times. This enhances the overall efficiency of inventory replenishment processes.

Joint inventory management

Some suppliers offer Vendor-Managed Inventory (VMI) services, where they take responsibility for managing stock levels based on agreed-upon criteria. This arrangement can streamline supply chain operations, reduce the administrative burden on the business, and ensure timely replenishment of inventory.

By relying on suppliers to manage stock levels, businesses can focus on sales and customer service, leading to a more responsive and agile inventory system.

Volume discounts

Negotiate volume discounts with suppliers, especially for high-turnover items or when purchasing in bulk, to significantly save costs. By placing larger orders, businesses can secure better pricing from suppliers, which positively impacts profit margins.

Additionally, volume discounts can provide a buffer against price fluctuations or decreased sales. For instance, a retailer can offer extra discounts if they notice a decline in sales without significantly affecting their profit margins.

A Quick Case Study of Walmart’s Effective Inventory Management

Understanding how major retailers like Walmart manage their inventory can provide valuable insights for small businesses looking to enhance their inventory control.

Walmart, one of the largest retailers globally, is renowned for its strategic supply chain practices. Managing inventory across thousands of stores and numerous distribution centers requires precision and efficiency. Here’s a look at the intricacies of their inventory management practices that can be adapted for smaller enterprises.

Cross-docking strategy

Walmart utilizes a sophisticated cross-docking system to streamline inventory flow and reduce storage costs. Cross-docking involves unloading products from incoming trucks at a logistics facility directly onto outbound trucks with minimal or no storage in between.

This system drastically reduces the time goods spend in the warehouse and reduces storage costs. For example, fresh produce is quickly transferred from distribution centers to retail stores, ensuring high inventory turnover and fresh products for consumers.

Real-time inventory tracking

Walmart employs advanced technology and an integrated inventory management system to track inventory accurately in real time. RFID (Radio Frequency Identification) product tags provide up-to-date information about stock levels, location, and movement.

This real-time visibility allows Walmart to make informed decisions about replenishment and distribution, minimizing excess stock and preventing stockouts.

Data-driven forecasting

Walmart uses sophisticated data analytics to forecast demand and optimize inventory levels. By analyzing historical sales data, market trends, and external factors like seasonal demand and economic indicators, Walmart can more accurately predict customer demand.

This predictive capability enables proactive adjustments to inventory levels, ensuring that inventory is not wasted and that the right products are available at the right time.

How A Small Business Implemented Effective Inventory Management Techniques

Incorporating effective inventory management techniques isn’t exclusive to large retailers; many small businesses have also harnessed these strategies to improve their operations. Here’s an example demonstrating how a small business successfully deployed advanced inventory management practices.

TerraSana is a Dutch organic food distributor that sells healthy food products across Europe. Sourcing from small family businesses and farmers worldwide, TerraSana experienced substantial demand growth. However, this success brought significant challenges in managing inventory effectively.

To maintain high service levels while managing costs, TerraSana needed to automate and optimize its inventory management processes.

Automated order processes

To streamline their inventory management, TerraSana implemented EazyStock, an advanced inventory optimization tool. This tool automates the ordering process, providing daily, optimized order proposals.

It considers various factors such as lead times, minimum order quantities, and order cycles while processing orders. This optimization minimizes stockouts and overstock situations by aligning inventory replenishment with actual demand.

Production planning

By analyzing historical sales data and current demand, TerraSana predicts the need for raw materials to ensure the timely production of finished products. This proactive approach helps avoid delays due to missing raw materials. They use this data to adjust their ordering schedules and stock levels accordingly, ensuring a smooth and efficient production process.

The result

With these strategies, TerraSana has automated its entire inventory management operation and successfully reduced stockouts while optimizing its stock levels.

Conclusion

Effective inventory management is about striking a balance where you neither overstock and tie up your capital nor understock and risk losing sales. Small businesses should take a proactive approach and implement robust inventory management tools to streamline supply chain operations and optimize inventory levels.

Continuous monitoring of inventory metrics such as turnover rates and order accuracy ensures that businesses remain agile and responsive to market demands. By prioritizing inventory management, you position your business for sustainable growth and increased profitability.

Frequently Asked Questions

1. What is the best inventory management software for small businesses?

The best inventory management software for small businesses often includes options like EazyStock, Linnworks, and SelectHub. Choosing the right software depends on your specific business needs, such as integration capabilities, scalability, and budget.

2. How often should the inventory turnover rate be calculated?

The inventory turnover rate should ideally be calculated on a regular basis, such as monthly or quarterly. This frequency allows businesses to track how quickly inventory is sold and replenished. It provides insights into sales performance and inventory management effectiveness.

3. What are some common mistakes in inventory management, and how can they be avoided?

Some common mistakes in inventory management include overstocking, understocking, inaccurate forecasting, and poor inventory tracking. These challenges can be easily avoided by deploying a robust inventory software and implementing certain management practices like conducting regular edits, optimizing reorder points, and more.